Results Produced by C-Cell

C-Cell software can produce over 50 results/applications which can all contribute to product or ingredient quality. If you are looking to assess baking quality, ingredients, snack foods or more; C-Cell calibrations can be tailored to meet a manufacturers needs. C-Cell results can be categorised into the below sections:

Colour

Brightness and Cell Contrast are based on grey scale values combining background colour of the flour and level of light reflected from different internal structures. Internal crumb colour, external crust colour and depth are measured.

Brightness/Cell contast are dimensionless values based on the monochrome 256 greyscale.

Colour is based on L*a*b* format commonly found within the food industry.

dimensions & shape

The area, maximum and average height, width and circumference are all measured for each slice. Concavity (top, bottom and side), Oven Spring (position, height, depth) and top shoulder and bottom roundness are measured for both sides of the slice.

cell size & elongation

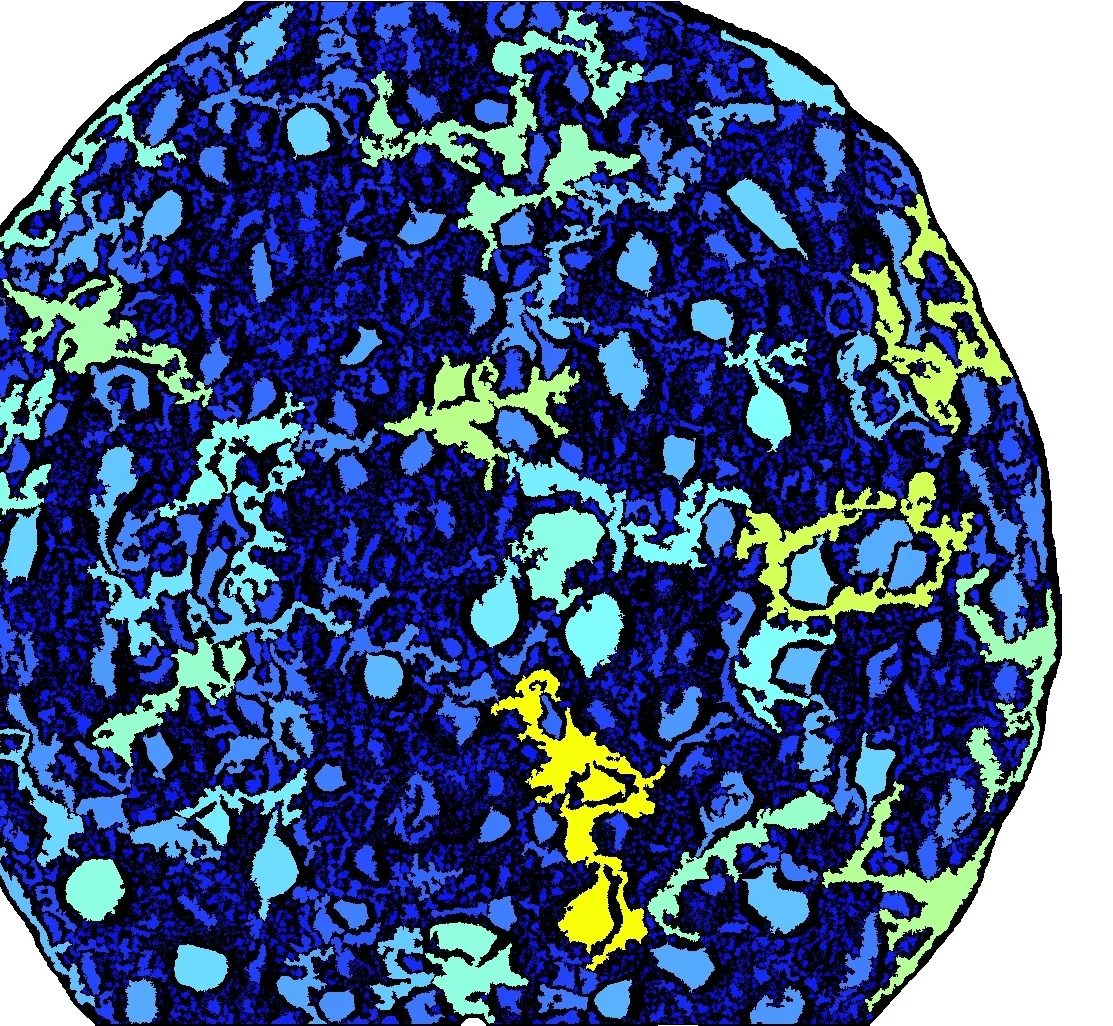

Individual cell analysis provides detailed information regarding number, size and distribution of cells throughout the crumb structure. Holes, Wall Thickness and Cell Areas & Volumes are quantified. Cell Elongation measurements using X/Y diameter co-ordinates for each cell provides a circulation map showing the axis of elongation and level of curvature of the internal crumb structure.

inclusions

C-Cell has the capability to determine inclusions within a product based on their L*a*b* colour e.g fruit or chocolate inclusions. Distribution of inclusions within the product are identified allowing the remaining internal crumb structure to be quantified.

External features

C-Cell can measure external features of a product such as sesame seeds on the surface of a burger bun or surface cracking of cookies to quantify uniformity of distribution.

bread score

Bespoke calibrations can be developed taking objective C-Cell data to create a product specific algorithm that correlates with the subjective scoring regime used within the bakery.