As the expectations for freshness, quality, and availability rise in the commercial baking sector, the implementation of smarter quality control and waste reduction strategies is essential to making production sustainable.

While markdowns and redistribution channels can ease the symptoms of waste, real progress comes from waste prevention achieved by harnessing data and intelligent quality control.

How does food waste impact the environment?

Food waste is among major sustainability threats facing the UK and wider world today, contributing significantly to climate change and environmental degradation.

According to the Waste & Resources Action Programme (WRAP), around 10.2 million tonnes of food are wasted each year in the UK alone, highlighting not only a massive economic cost, but an environmental one too.

Much of this wasted food ends up in landfill, where it gradually decomposes while releasing methane - a greenhouse gas more potent than carbon dioxide when it comes to trapping heat and powering the devastating effects of climate change.

Beyond the emissions from waste itself, the energy, water, and raw materials used to produce, transport, and store this food are also squandered, further amplifying the overall environmental impact.

Bakery waste and surplus: the two sources of inefficiency

In commercial baking, waste and surplus arise for different reasons but both are the result of inefficiencies.

Baking waste largely occurs due to production errors and rejections as goods fail to pass quality control measures or meet customer expectations, while surplus stems from overproduction and demand misalignment.

Addressing both effectively demands a shift from reactive responses to proactive, data-informed solutions.

Tackling unsold goods and overproduction

How often have you seen freshly-baked bread, cakes, and pastries reduced in the supermarket aisles? This is the everyday reality of food waste in the UK.

Despite redistribution schemes and waste-reduction apps like Too Good To Go, the mismatch between customer demand for fresh, fully-stocked shelves and the industry’s need for efficiency drives overproduction and the increase in unsold goods.

The UK retail sector alone contributes around 270,000 tonnes of food waste each year, with supermarkets being a major source. Much of this waste represents not only lost profit, but also an unnecessary and negative environmental impact.

To tackle this, bakeries must move towards adopting a more flexible, data-led response to their customers’ buying behaviour.

By monitoring real-time sales data and a selection of relevant external factors, including weather patterns, holidays, and marketing activity, forecasting can stay agile, allowing bakeries to adjust the quantity and distribution of goods in line with demand.

Reducing the amount of rejected products

Rejected bakery products are another substantial source of food waste in the commercial baking industry.

A direct result of inconsistencies in the baking process, these products are often edible but can’t be sold due to their cosmetic imperfections.

Whether they have a cracked top, misshapen form, or inconsistent colouring, just like unsold goods, these imperfect items tend to end up in the same place – landfill.

Even the smallest errors in the baking production process can create large-scale waste if not swiftly identified and rectified.

These inefficiencies can be caused by a wide range of issues, such as poor temperature control, equipment faults, and even inaccurate measurements.

The solution? Effective quality control is vital for reducing bakery waste by catching errors early, preventing ingredient overuse, minimising product defects, and enabling continuous process improvement.

Without precise monitoring and consistent standards, bakeries not only risk higher rejection rates and resource waste, but they also face increased operational costs.

By making changes to their manufacturing and distribution operations, one of our well-known customers, Warburtons, has avoided sending any of their food products to landfill since 2015.

Combining proactive and reactive solutions

Looking beyond proactive prevention, some of the more innovative bakeries are finding new, reactive ways to tackle excess waste by treating it as a resource rather than a liability.

By upcycling bakery by-products and ingredients, such as turning spent grain or pulp into flour, this approach cuts waste and creates new, more sustainable product lines.

Equally important for the reactive reduction of food waste is collaboration across the supply chain.

Bakeries that choose to work closely with suppliers, distributors, and even competitors can facilitate shared efficiencies through joint logistics, redistribution of surplus stock, and partnerships with food rescue organisations.

And it works - since 2017, Warburtons has redistributed over 345 tonnes of product (equivalent to 430,000 loaves of bread!) to help those in need through their partnerships with Fareshare, Company Shop, and other charitable organisations.

The tangible risks of inaction

And as a major environmental issue, commercial food waste is strongly frowned upon in the UK.

Without smart quality control, an increase in wasted resources and goods is inevitable, directly contributing to greater landfill impact and higher greenhouse gas emissions.

Companies that fail to recognise the severity of this issue and implement necessary measures are likely to face public criticism, investor concern, and long-lasting brand damage.

Crucially, failing to introduce appropriate bakery waste reduction measures can also lead to higher rework costs, an increase in scrapped products, and expenses associated with disposing of faulty goods.

How smarter quality control is shaping the future of sustainable baking

Emerging technologies such as automated baking analysis systems are enabling more precise quality control and data-driven decision-making in the commercial baking industry.

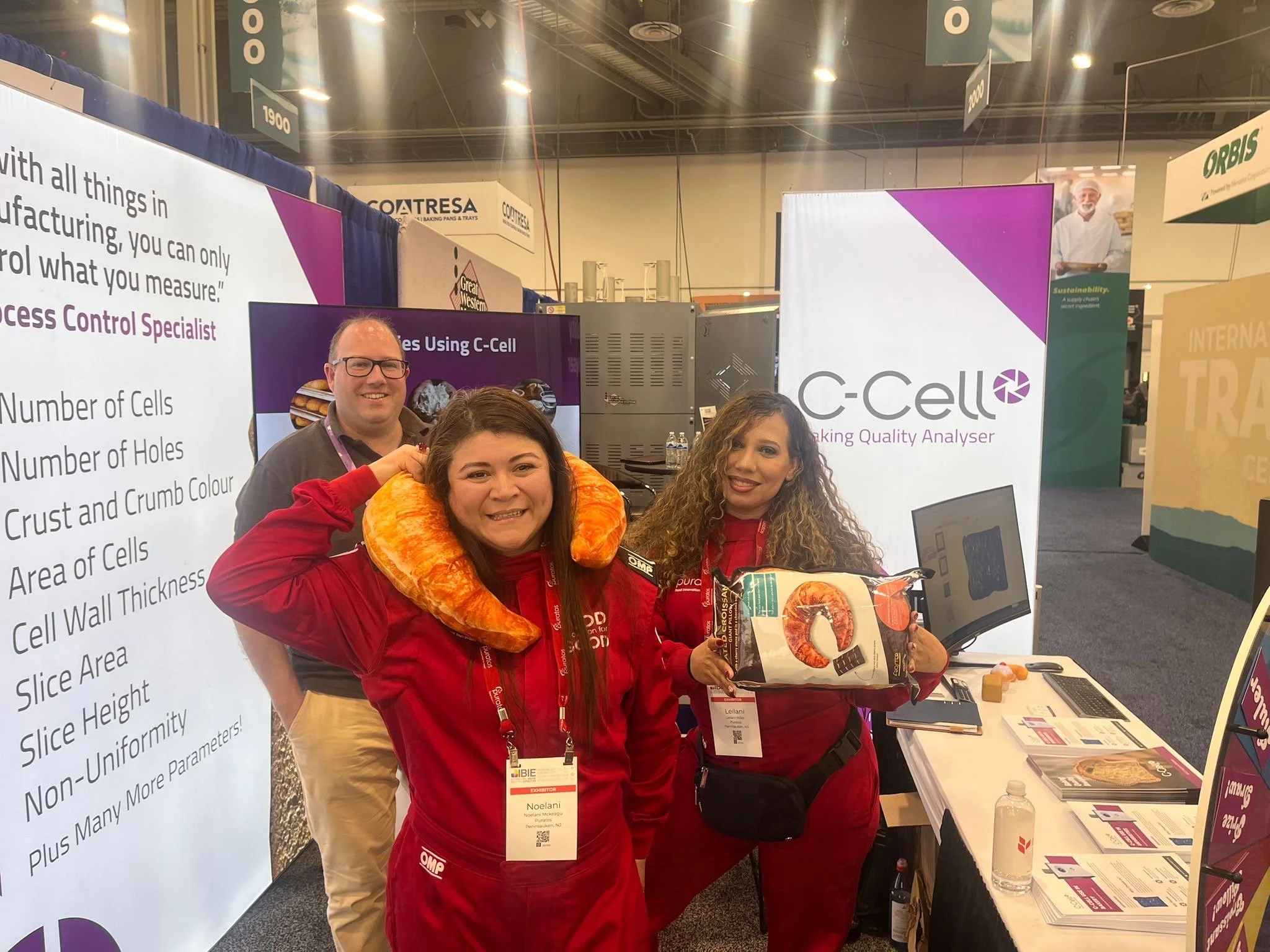

Applications like C-Cell baking analysis systems offer valuable, quantifiable data that can inform bake quality and tackle wastage. By assessing various parameters such as cell size, distribution, density, and colour, such systems can assist bakeries with:

• Identifying inconsistencies early in the baking process

• Analysing ingredients against permissible contaminant levels

• Optimising formulations and process settings

• Reducing rejected batches and ingredient waste

• Improving return on investment through greater efficiency

These kinds of efficient, data-led solutions highlight the increasing importance of proactive prevention, underpinning a more sustainable future for commercial baking.

Want to learn more about how the C-Cell baking analysis tool can support environment-friendly baking? Talk to our expert team today.